Unfortunately, clogs can happen. Here are some ways to get you back up in running in minutes.

- First, heat up the extruder to at least 240C and pull out what's already in the hot end if possible. You may need to use tweezers. You may need to open the filament latch all the way to see the stuck piece of filament. You can open the filament latch by removing the screws with the springs on them and fully open the latch. Now look down into the loading hole. If you see some left over filament, use tweezers to extract it. Make sure the extruder is at least 240C.

- Next, take a fresh piece of PLA about 8 inches long and straighten it out. Feed the new PLA manually down, into the hotend, and see if it is coming out of the nozzle.

- If there is material coming out of the nozzle, go ahead and turn down the extruder to 145C with the filament still in the nozzle. Manually pull the filament out of the nozzle, which will take with it most of the debris that is stuck in the nozzle. You can repeat this step as many times as you think is needed to clear any old debris from the nozzle.

- If there is no material coming out of the nozzle. While the hotend is at 240C, you can try using a long sewing needle or 1.5-2mm alan wrench to feed it down in to push through any leftover plastic that may be stuck in the hotend. Another way to clear the hot end would be to use a small guitar string or wire bristle and feed it up through the nozzle while it's heated up to clear any obstruction.

- If the past two steps didn't work, you can take the hotend out of the printer to get a better look at the problem.

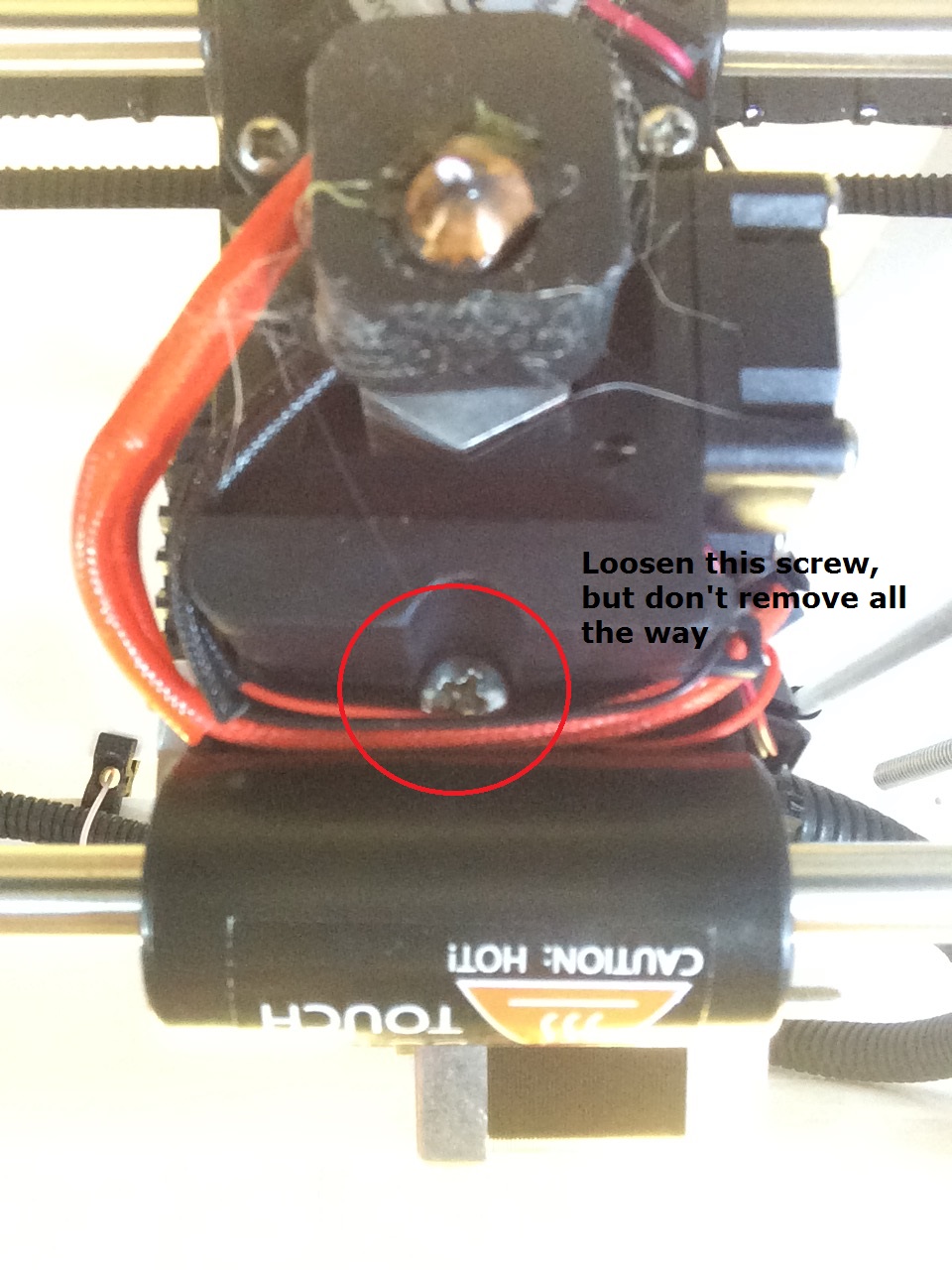

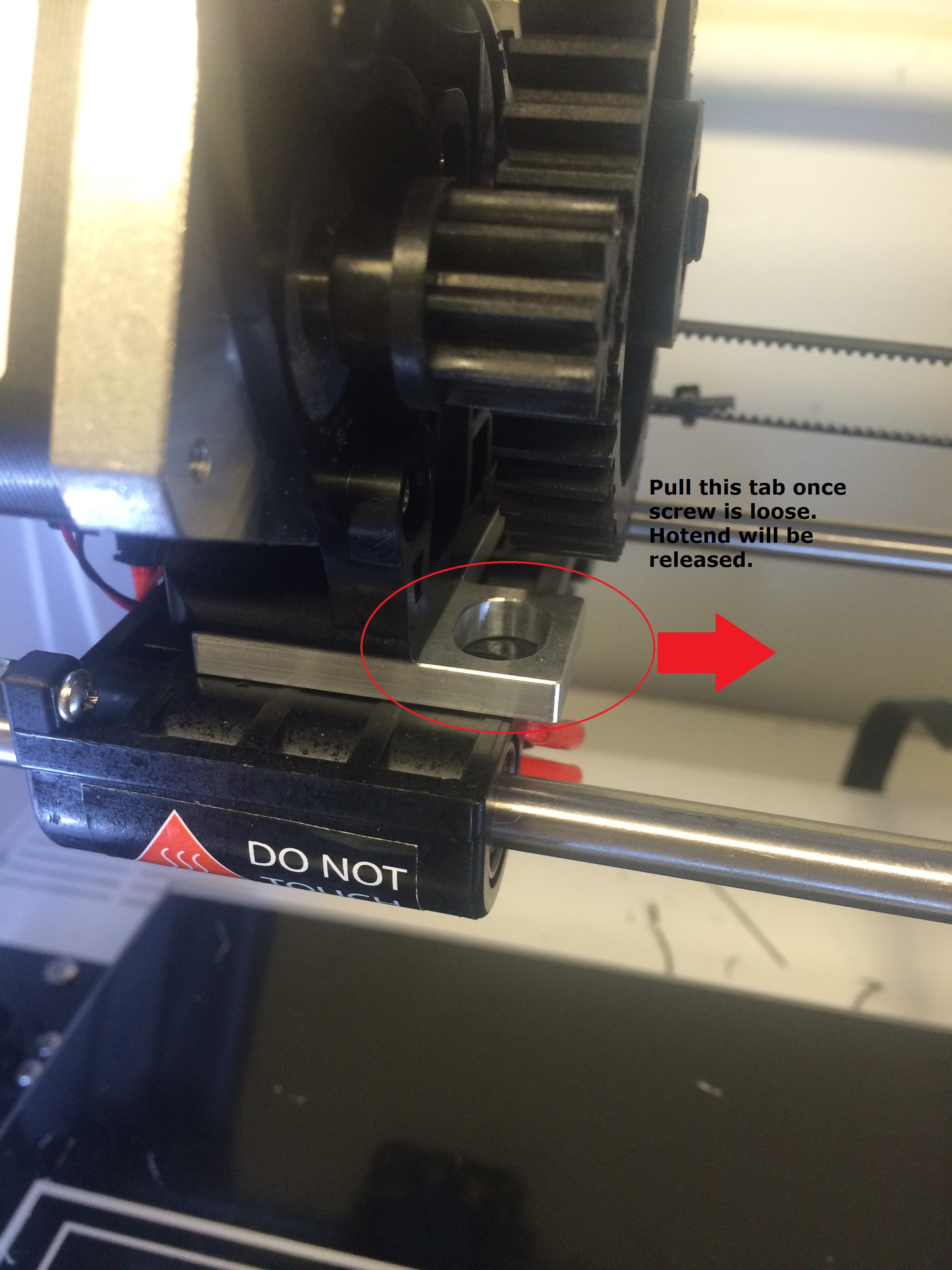

If you need instuction on how to remove the hotend: Hotend Removal Instructions. These pictures show how to operate the quick release and to easily remove your extruder.

NOTE: Keep the extruder hot while loosening and tightening to prevent breaking off the nozzle.

- You can heat the hotend up and turn the hotend upside down while it's hot to let the plastic ooze out slowly. Grab the hotend with some pliers so you do not touch it with your bare hands. You will be able to grab the extra material once it starts sliding out the top of the hotend and will be able to pull all of it out with the tweezers.

- Then, while the hotend is at 240C, with a fresh piece of PLA feed it down into the extruder as far as it will go. Now, let the hotend cool to 145 C, then pull it out while attempting to pull any remaining bits of burnt or bad plastic clogged in there.

- You might need to take the nozzle tip off and replace or clean it.

Also here are some great ways to prevent a clog from happening again as well as improving extrusion

Here's a video that helps you to see how the hotend is put together.

How to remove stuck filament with tweezers:

Comments

0 comments

Please sign in to leave a comment.